MATRIX PROJECTS

P2O5 CONVEYING

November 1, 1999

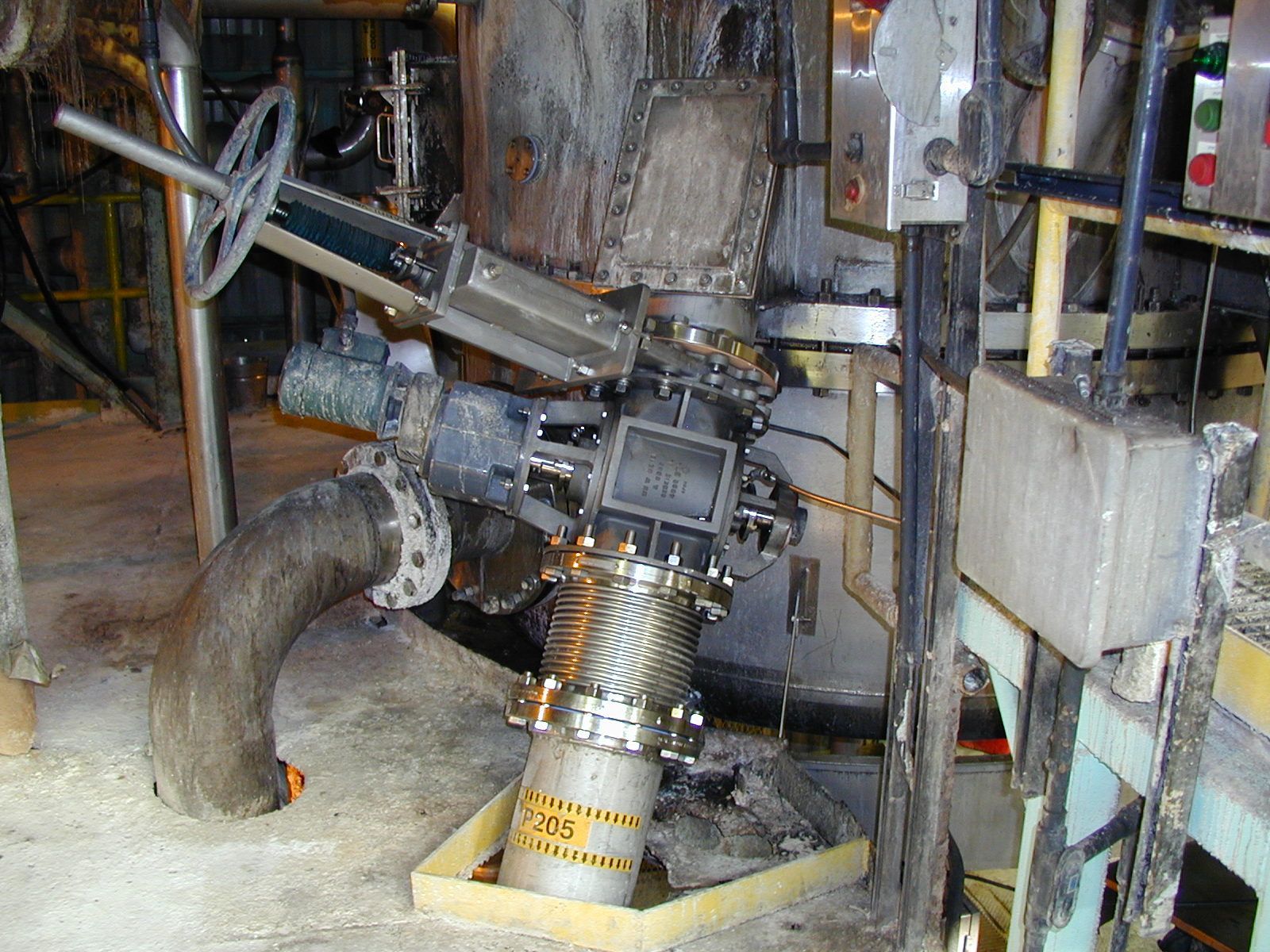

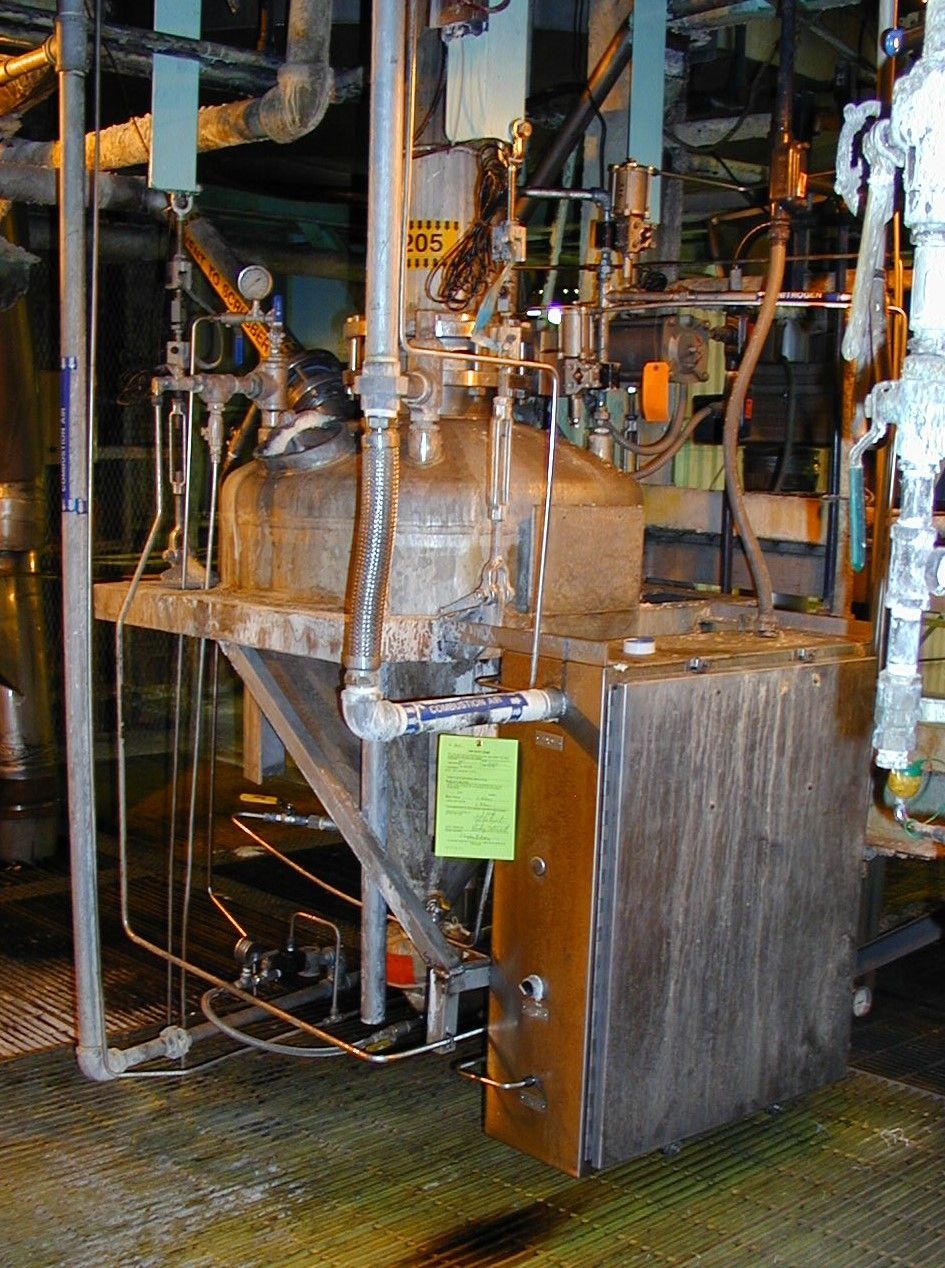

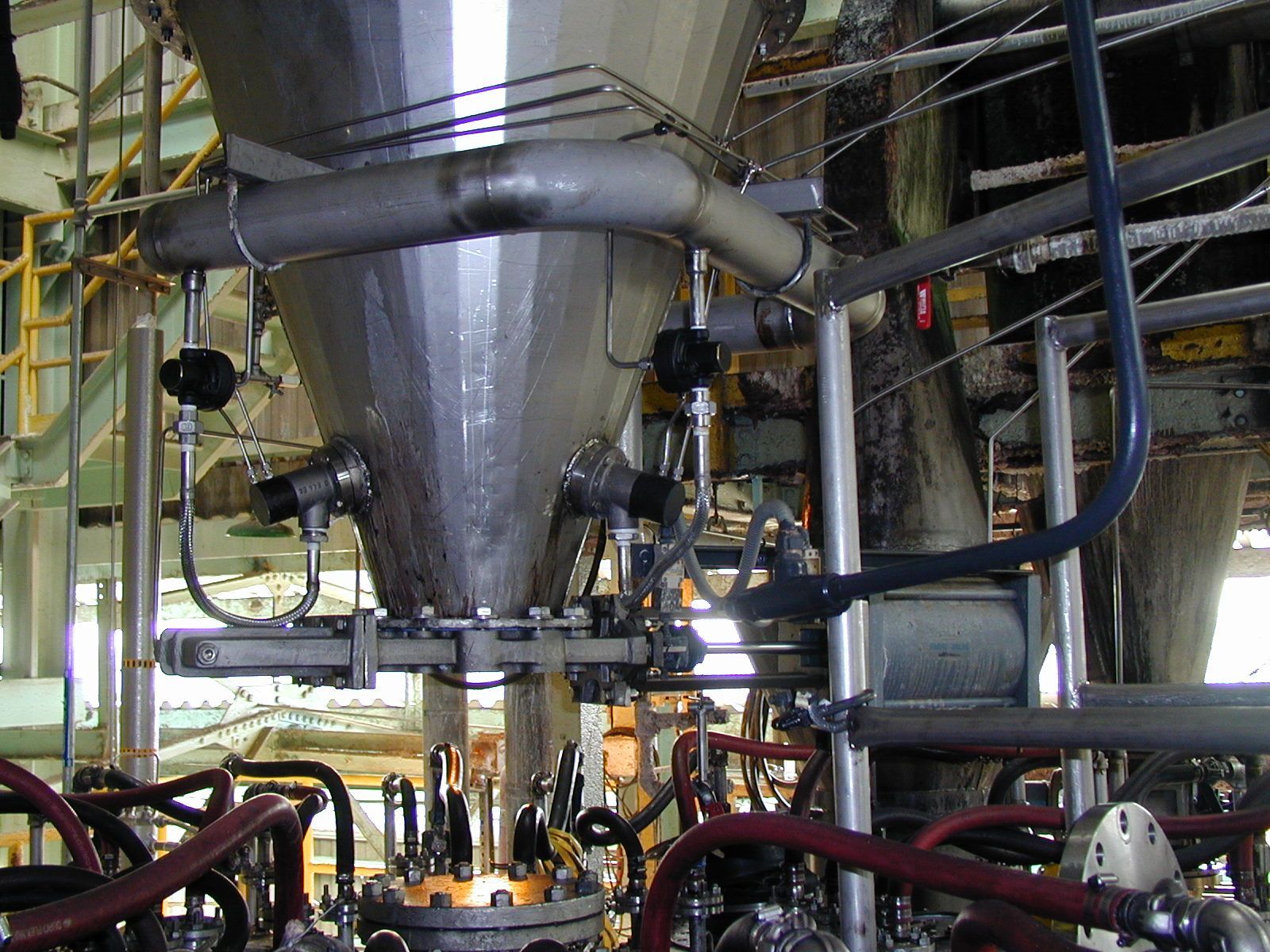

Matrix Engineering was consulted and hired to rehabilitate a pneumatic conveying system for handling phosphorus pentoxide (phosphoric acid anhydrous). This material is very corrosive and extremely hygroscopic - reacting with water to form hot phosphoric acid. Matrix provided the mechanical, electrical design along with the control system integration for the project. A dense phase transporter was rebuilt for transporting the material to a bed hopper which was vented to an existing scrubber system. Matrix also specified and provided the controls for a gas compressor which took existing dry combustion air at 25 psi and compressed to 80 psi for use in our dense phase system. Nitrogen purges were also designed for keeping the system dry between batches as well as providing a moisture free blanket over the bed hopper. Much of the design was centered around keeping the system dry and not sticky, the product dry and free flowing, and keeping the air supply dry and clean. Design efforts also emphasized maintenance and the ability to wash down and dry the system easily after a production cycle.