CLASS II COMBUSTIBLE DUST COLLECTION SYSTEM

CORROSIVE / COMBUSTIBLE IODINE DUST

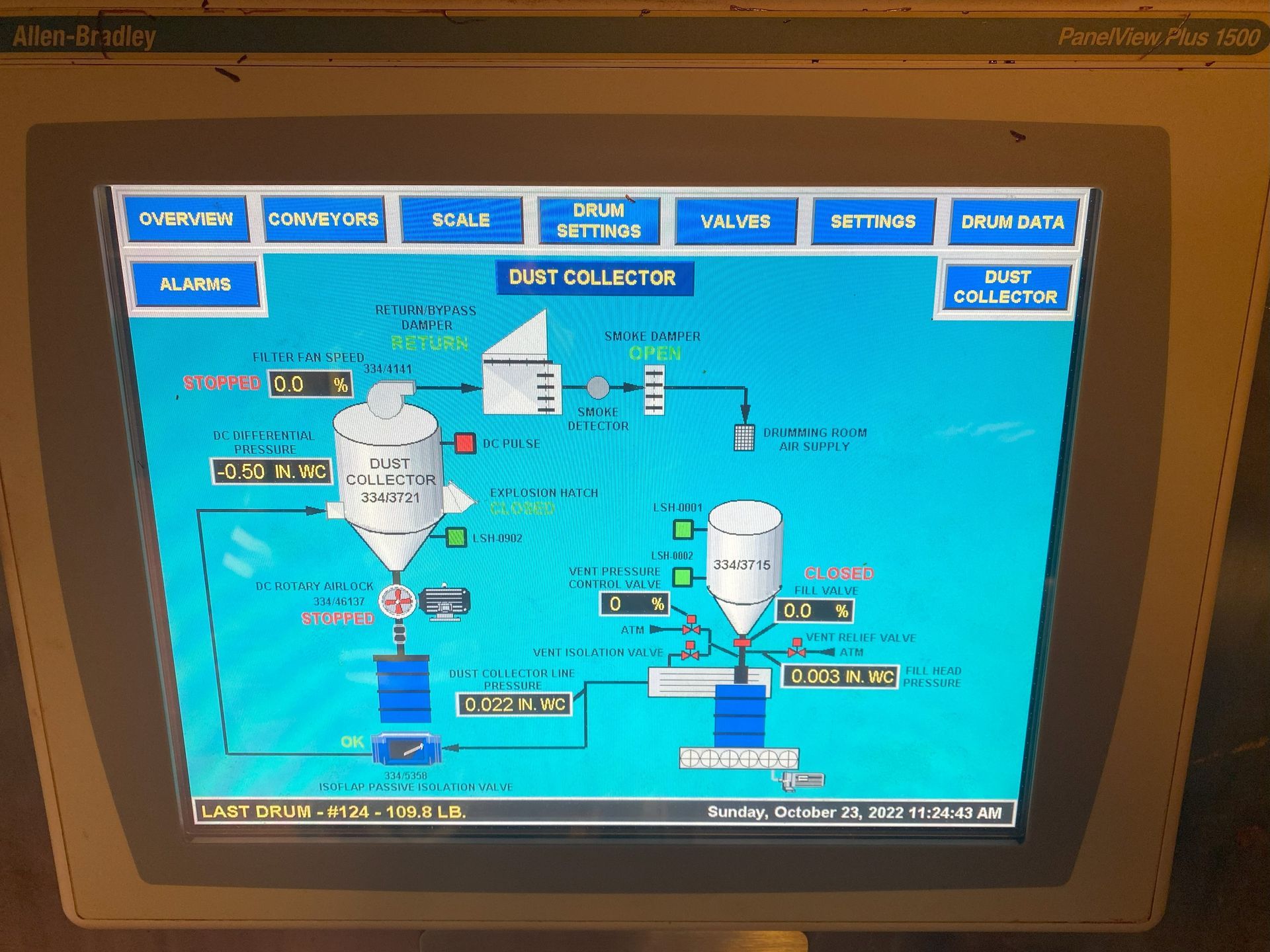

Matrix designed and supplied a dust collection system for pharmaceutical grade of corrosive and combustible dust in a Class II environment. In order to meet NFPA criteria for handling combustible dusts, the filter was equipped with a rupture panel as well as an ISOFLAP isolation valve that sensed a potential backdraft from explosion within the inlet duct. The system ventilated a climate conditioned space and as such, had an additional extra level of filtration and returned its discharge back to the room. Due to the possibility of fire and/or explosion, the system utilized a smoke detector and automated bypass damper to prevent smoke from being blown back into the room.

Our PLC based control system also utilized variable speed on the fan control for maintaining proper vacuum levels within the system, despite the differential pressure through the filter elements as well as interlocking the fan motor with the explosion/fire safety instrumentation.