MATRIX PROJECTS

DRUM FILLLING CONTROL SYSTEM

Darren Jarvis • October 31, 2022

CLASS I AREA PLC CONTROLS

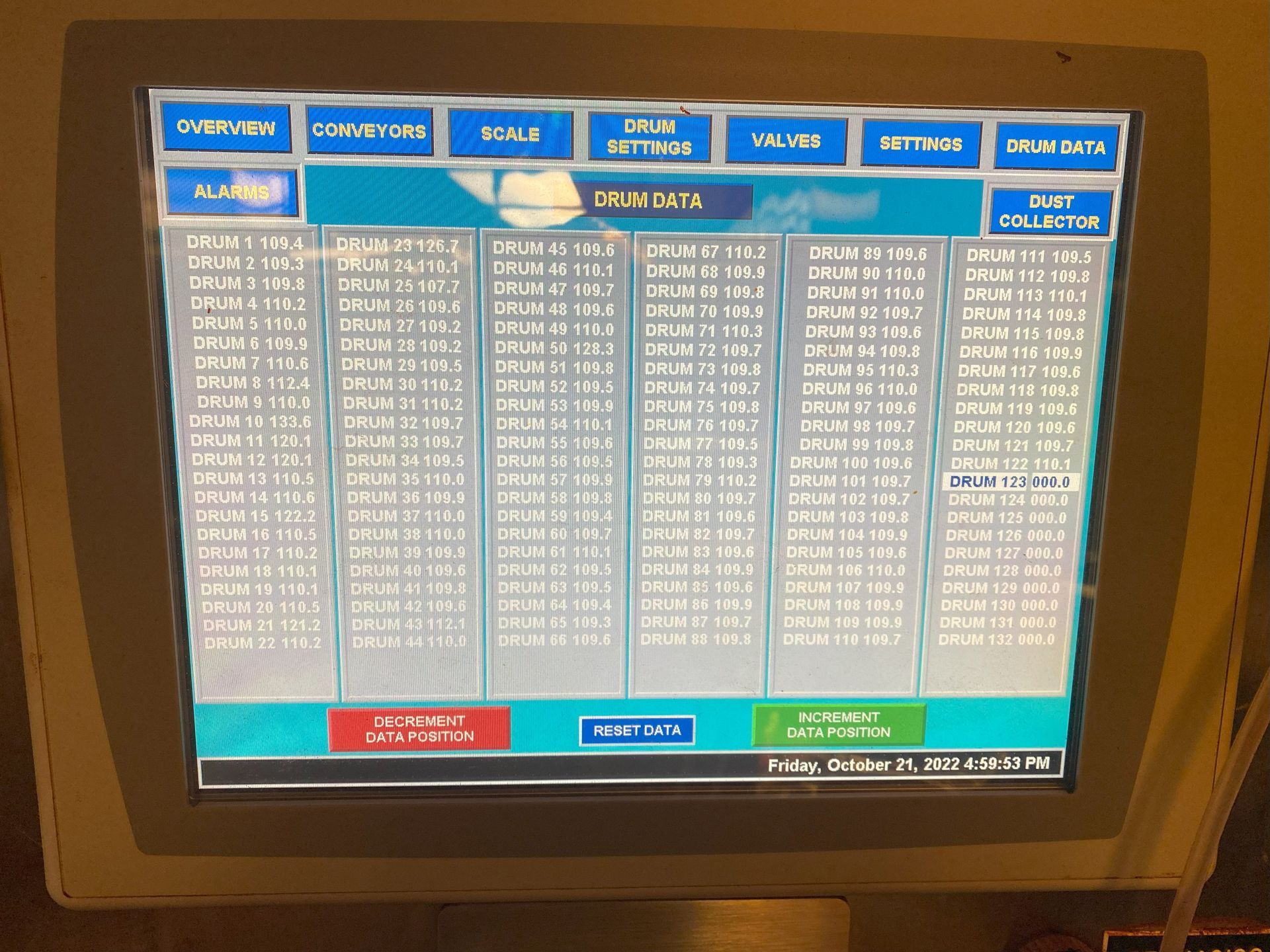

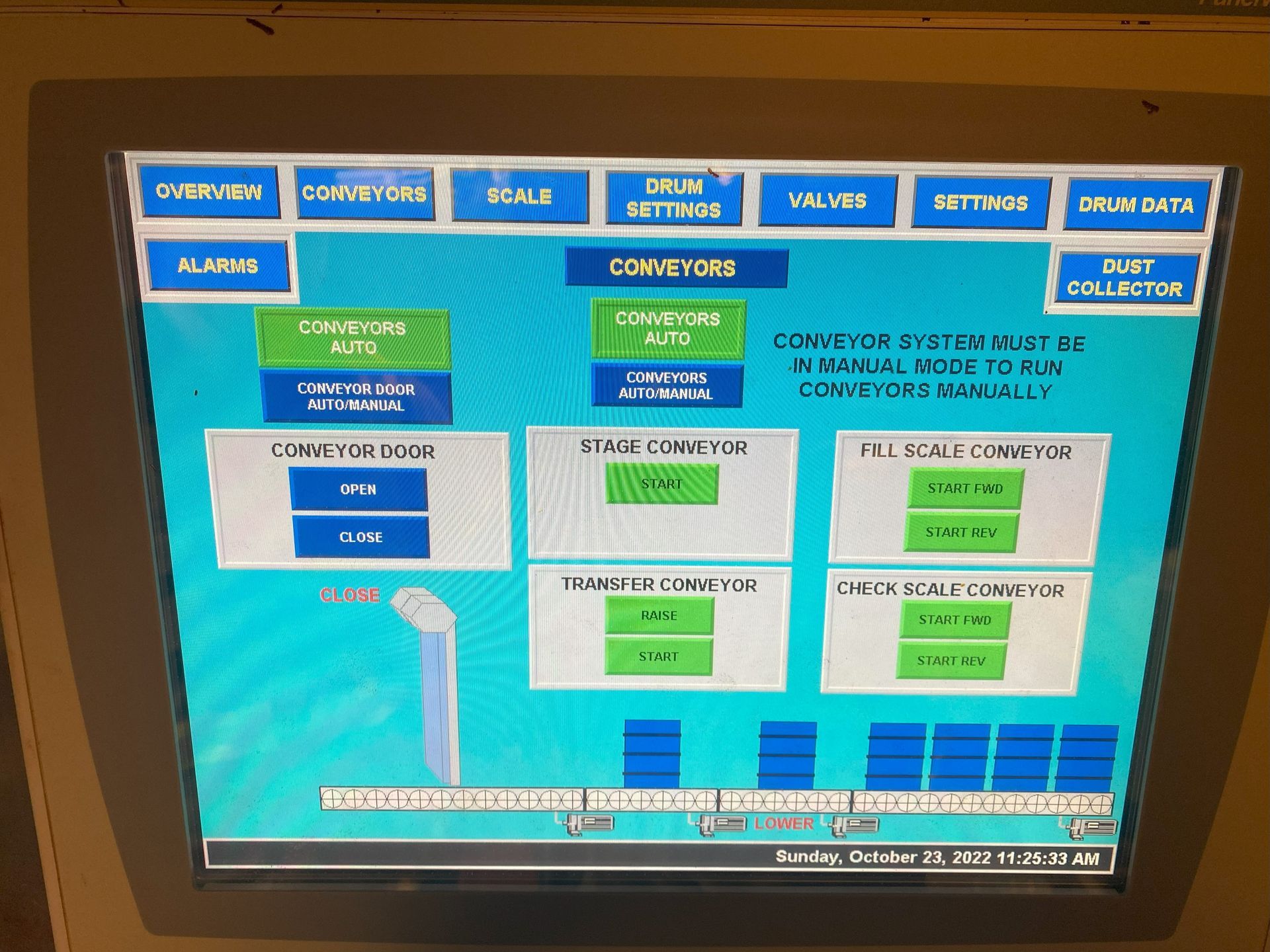

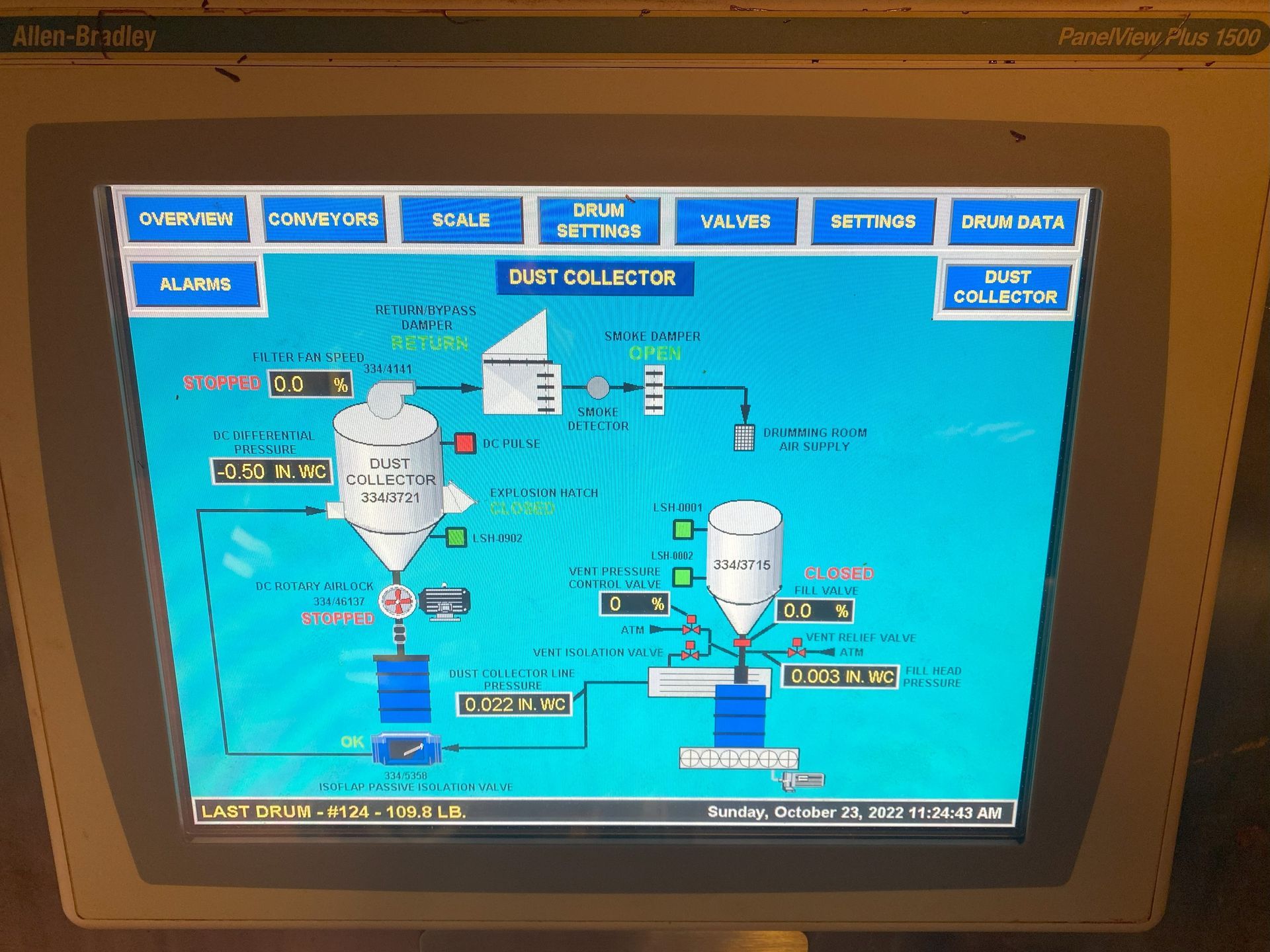

Matrix designed and supplied a custom drum filling system for pharmaceutical grade of corrosive and combustible dust in a Class II environment. A variable / fast closing gate was used for bulk and dribble fill of the drum. A check weigh station is below powered rollers beside the filling station where the liner is tied and the drum lid fastened. The drumming system is capable of filling different drum sizes as well as storing drumming campaign batch data for drum traceability. Automated roller conveyors were employed for handling empty and filled drums.

A key element to the success of the filling system was the instrumentation and minute vacuum control for prevention of fugitive dust while maintaining fill accuracy.