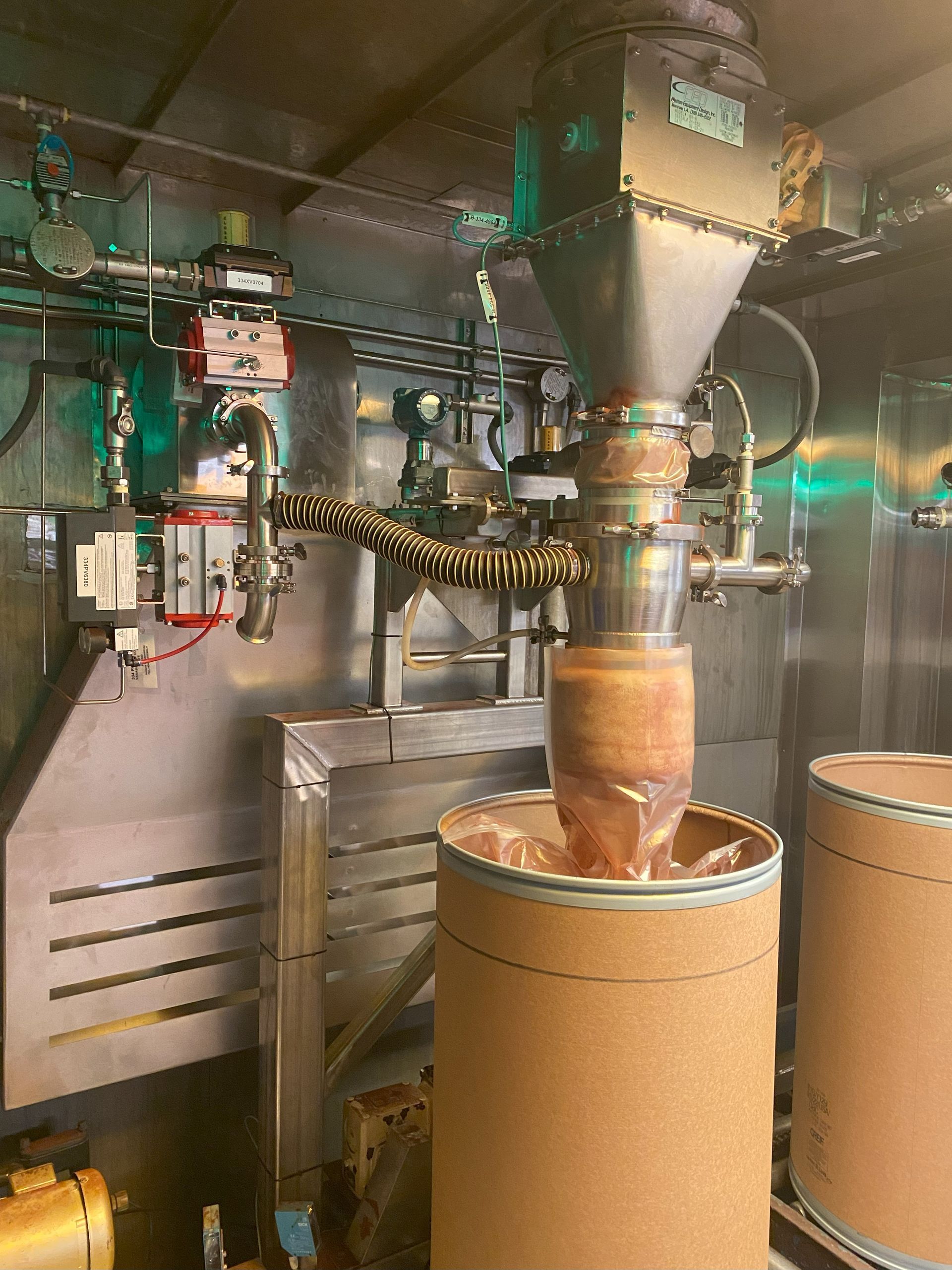

DRUM FILLLING SYSTEM OF COMBUSTIBLE DUST

PHARMA GRADE CLASS II DIV 1/2 POWDER PACKAGING

Matrix designed and supplied a custom drum filling system for pharmaceutical grade of corrosive and combustible dust in a Class II environment. The drumming system was capable of filling of filling different drum sizes as well as storing drumming campaign batch data for drum traceability. Automated roller conveyors were employed for handling empty and filled drums. A check weigh station is below powered rollers beside the filling station. A variable / fast closing gate was used for bulk and dribble fill of the drum.

One of the primary challenges was the reduction and capture of fugitive dust while maintaining the accuracy of the fill. This required precise control of minute vacuum levels for de-dusting of the interior of the drum liner as well as significant / high velocity dust capture for any that might escape. Our mechanical expertise with proper instrumentation and control allowed us to accomplish this with the same dust collection system. The drumming room was a climate / dehumidified conditioned space. Our high velocity slotted ventilation hood drew a significant air change within the space. To maintain climate control, the ventilated air was filtered twice and returned to the room. Our attention to the placement of the this returned air back into the room created a draft and by its direction helped move any fugitive dust into the the hood.