MATRIX PROJECTS

FLUIDIZED BED DRYER

March 2, 1999

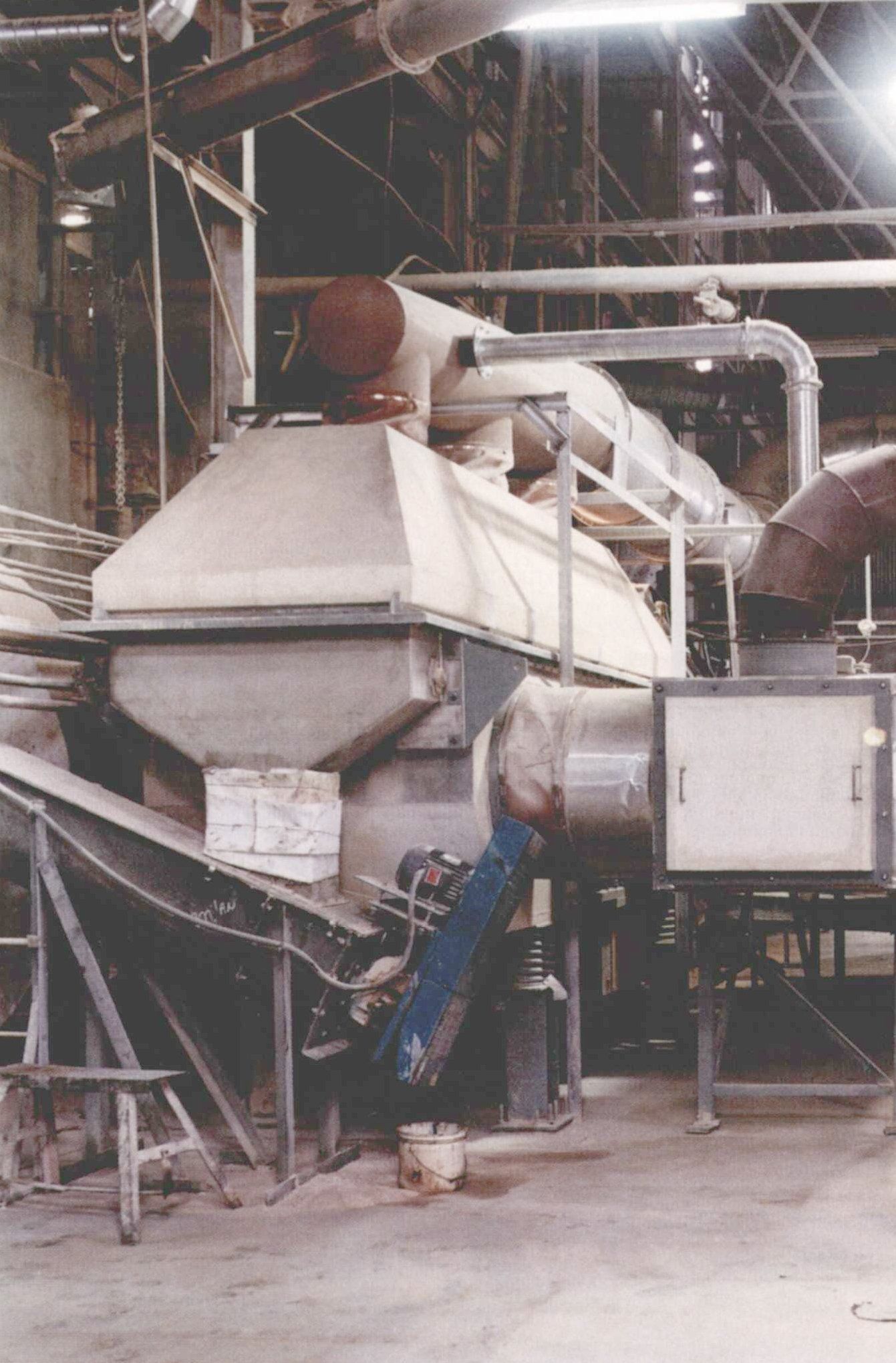

Designed a new system for the milling and drying of freshly mined tripoli stone. Included was a new vibrating fluid bed dryer, associated dust collection and fans, a new hammermill, and a number of feed and take-away conveyors. Design included lay-out, foundations, bulk handling, dust control, power and controls. The project replaced a rotary kiln dryer installed in the year 1919. The replacement was engineered to minimize downtime and took only 5 days to complete. The project resulted in a 45% savings in natural gas just six short months prior to the natural gas shortage price hikes. This project was featured in Powder and Bulk Engineering Magazine, July 2000 issue.

Powder & Bulk Engineering Article (PDF)

More Projects & News

Site Map

Contact Info

112 Walter Jetton BlvdPaducah, KY 42001, United States

Website Design & Hosting by Arterburn.com