MATRIX PROJECTS

HODGE, LOUISIANA DUAL PETROLEUM COKE DENSI-FEED™ SYSTEM

October 2, 2005

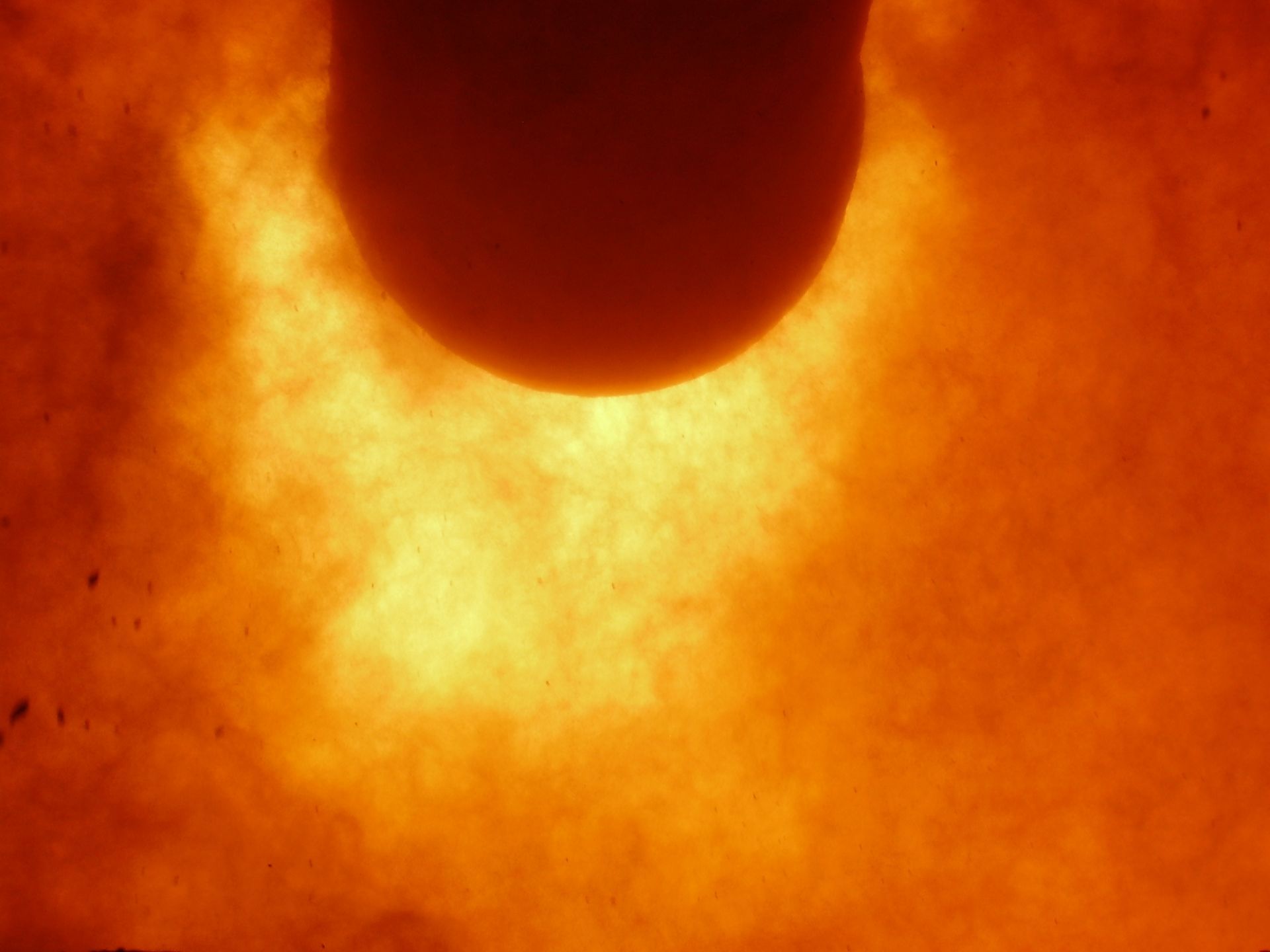

Matrix provided the complete engineering package for a dual discharge petcoke delivery system for Smurfit Stone Containerboard Division in Hodge, Louisiana. The system was designed to feed two lime kiln burners from a common 180 ton silo. A dual discharge hopper bottom was specifically designed for two petcoke DENSI-FEEDERS. It included dual pneumatic convey systems with variable rate blowers to deliver petcoke to the Coen burners in accordance with the manufacturer's specific air flow requirements. The convey distance of the petcoke was in excess of 600 feet. The system allowed the mill to report substituting up to 90% ground petcoke for natural gas in each of their lime kiln burners. The control of the Matrix feed equipment was integrated into Smurfit Stone’s existing DCS. Matrix provided all the civil/structural, mechanical, and electrical engineering for the project.

The project was commissioned shortly after Hurricane Katrina during very high natural gas prices. As a result, the mill was able to pay for its investment on 2 Kiln Fuel Systems WITHIN 4 MONTHS!