MATRIX PROJECTS

BOWLING BALL BALANCE SYSTEM CONTROLS

November 25, 2003

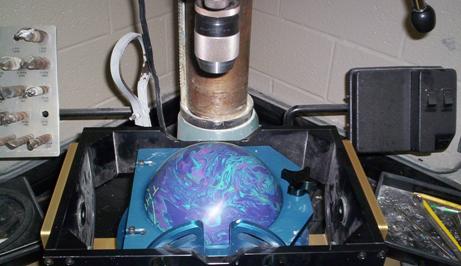

Matrix Engineering provided the low cost control system to locate and mark the “top weight” in a bowling ball which cannot be seen on the surface of the ball. This top weight directly affects the performance of the bowling ball and must be precisely located and marked so it may be drilled for use. The control system utilized a PLC, servo motor and drive, strain gauge, and a touch-screen operator interface.

In addition to locating and marking the top weight, the control system produced the actual weight of the “top weight” in ounces as well as the total weight of the ball. The total system cycle time was kept between 20 and 30 seconds which was a key factor in production.