Reactor Feed of Phosphorus Pentoxide

P2O5 Batch Feeding System

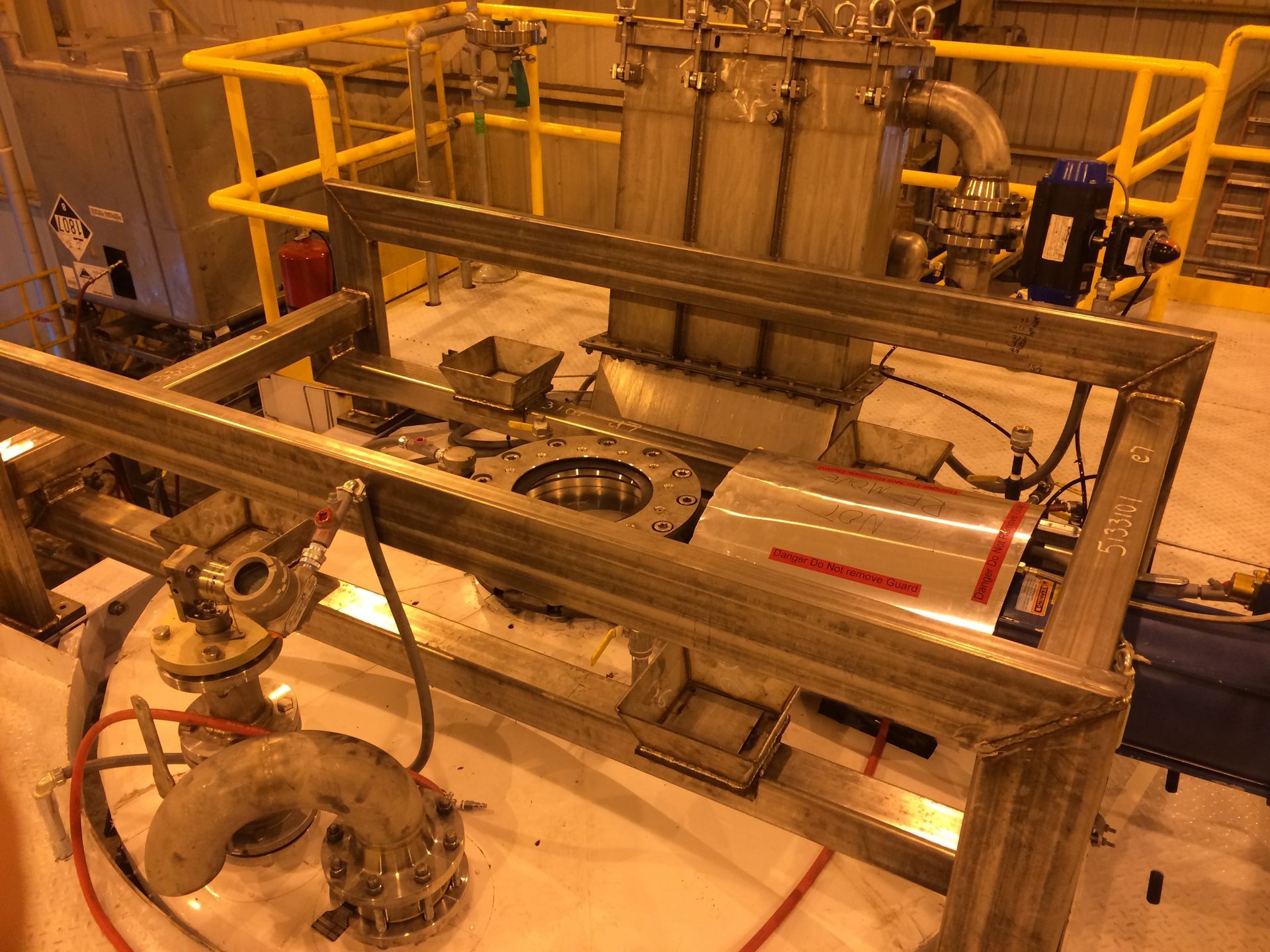

Matrix designed and supplied a custom batching system to a reactor of the extremely difficult powder, Phosphorus Pentoxide (P2O5). The powder is highly hygroscopic and forms a corrosive hard/sticky crust when exposed to moisture or humidity. Our batching system was designed to receive the powder from IBC totes and precisely meter it into a wet reactor. When P2O5 is in contact with water, it reacts exothermically with extreme heat release and hot phosphoric acid steam.

Using our sealed tote transfer design, we were able to control the infiltration of moisture and lumping inside the batch hopper and our rugged VSVP Auger could accurately and predictably feed the powder into the reactor below utilizing loss in weight. Our custom feed screw utilized a special sealing valve on the discharge to prevent moisture from penetrating our batching system from the reactor below.

The system was also designed for a Class I Division 1/2 environment.