MATRIX PROJECTS

PVP-I DRUM FILLING

January 2, 2003

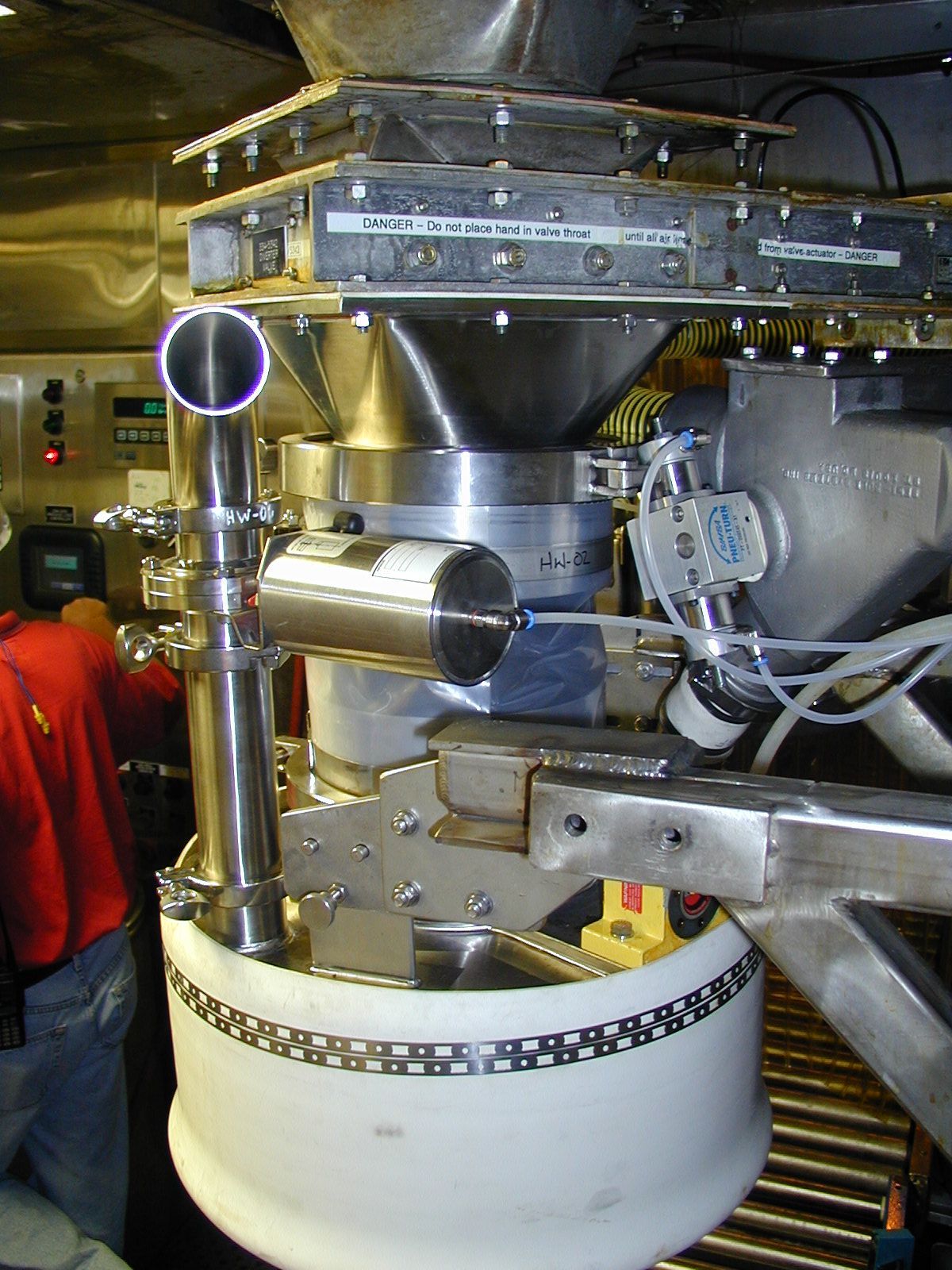

Matrix Engineering provided mechanical and electrical engineering along with controls for a sanitary drum filling system in a Class I Div 2 environment. The mechanical engineering package included detailed design of the drum fill head for an inflatable seal and improvements in dust control during filling. A smooth bore flexible connection was custom designed to prevent ledges for product to rest. A batch fill weighing control system with HMI was designed for filling within 0.2 lb on a 110 lb drum.

The drum filling system had be recently replaced by another firm and was unable to consistently hit the target weight tolerance. Matrix responded immediately with a retrofit design that met the specification and satisfaction of the plant engineers and operators.

Over the years, Matrix maintained this system with check scale upgrades, automated fill and check conveyors, as well as a powered accumulated drum staging conveyor.